Dust Extractor Vs Shop Vac Can Be Fun For Anyone

Wiki Article

What Does Dust Extractor Vs Shop Vac Mean?

Table of ContentsThe Ultimate Guide To Dust Extractor Vs Shop VacThe Single Strategy To Use For Dust Extractor Vs Shop VacGetting My Dust Extractor Vs Shop Vac To WorkThe Only Guide for Dust Extractor Vs Shop VacThe Buzz on Dust Extractor Vs Shop VacThe Definitive Guide for Dust Extractor Vs Shop Vac

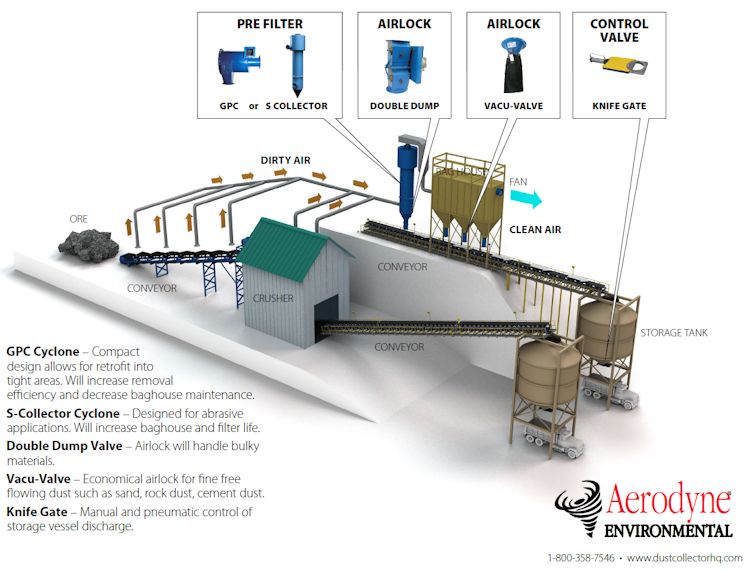

The difficulties for foundry dust collection systems focus on crystalline silica dirt, carbon monoxide gas, as well as heat, which are harmful mixes. These elements make conference air quality requirements difficult as well as requiring. For that reason, when picking a dirt control system for a shop, the very first factor to consider is the capability of the unit to stand up to rough as well as hazardous office conditions.Aside from the evident problems, the picked tools needs to meet the regulations of OSHA, the EPA, as well as the NFPA. To satisfy those requirements, dirt collection systems use shakeout units, collection hoods, thaw, mold putting, cooling down hoods, as well as exhaust heaps. Pleated bag as well as cartridge-style enthusiasts have a very effective filtration system as well as a compact size and reduced pressure drop.

Layer, or thermal spray, uses warmed product to metals to coat their surfaces. Dust collection systems for this sort of procedure have to be especially made to fit the sort of finish being used. The function of the system is to manage and minimize overspray and also dust. The normal thermal spray dust control system uses air ducts to relocate air to the collection gadget.

Little Known Questions About Dust Extractor Vs Shop Vac.

Though presumably likely to raise air flow and also movement, this sort of service may mishandle and waste power. The design of the booth relies on the force of the air going into the cell or cubicle. For many systems, it is essential to have a slight vacuum in the cubicle to avoid possible positive stress.An additional method is merely positioning the make-up air connection on the top of the booth. Despite the layout, it is very important for the cleansing of the air to have cross air flow. A lot like a cleanroom, airflow in a thermal spray booth can be either horizontal or downward, though the down style is best for dirt collection systems. dust extractor vs shop vac.

The pharmaceutical industry is a highly managed market with comprehensive and specific regulations. Dust from pharmaceuticals is produced mainly during the production as well as product packaging of items - dust extractor vs shop vac. Each action of generating a medicine, which includes granulating, drying, mixing, pushing, layer, and grinding, generates large amounts of dirt that need to be removed.

How Dust Extractor Vs Shop Vac can Save You Time, Stress, and Money.

HEPA filters are commonly located in pharmaceutical dirt control systems since they are the most efficient and also reliable. Similar to a shop system, they are set up as a secondary protection to attain no discharges. Recycling produces a great deal of dirt as a natural outcome of diminishing things to their raw materials.

Dust originates after products are shredded, crushed, or have paint or lacquer removed. All reusing facilities are required to comply with air high quality standards. As they function to satisfy quality criteria as well as control pollutants, they have actually identified that dirt control is a major issue, leading to the large use dirt collection systems to mitigate and also contain the trouble.

The 5-Minute Rule for Dust Extractor Vs Shop Vac

When manufacturers select a dirt control system, they are advised by producers concerning the kind of system that would certainly best fit their demands since buying and also installing a dust control system is a major financial investment. Particle matter comes in right here a wide range of forms, go to this site from silicon dirt to wood chips as well as sawdust.Below is a list of the sorts of particles that dirt collection systems can eliminate. Plaster Plaster calls for a high-efficiency baghouse system capable of operating at temperatures near 428 F (220 C). Felt Felt is utilized in clothing manufacturing and also requires dust collection systems at three stages of the process.

Sawdust This is the most common product eliminated by dust collection systems. Cartridge or baghouse techniques can be utilized, with baghouse being the most efficient.

Top Guidelines Of Dust Extractor Vs Shop Vac

Fabric filter bags in a cartridge system are the most effective technique for collecting dirt. Dirt collection systems are covered to include the dirt and clean the air.

With the intro of dust collection systems, employees are more secure as well as more secured. Sugar Sugar dirt is the by-product of the production of sweet.

Dust Extractor Vs Shop Vac Can Be Fun For Anyone

A baghouse system is the preferred system. Rice Dust Rice dust has very fine as well as minute bits that build up during the manufacturing of rice-based items. A dirt collection system is needed for the security and also safety and security of employees. Silica Silica is one of one of the most usual materials on planet. It is a main component of numerous manufacturing procedures, such as the manufacturing of glass, ceramic floor tile, concrete, and also asphalt.Report this wiki page